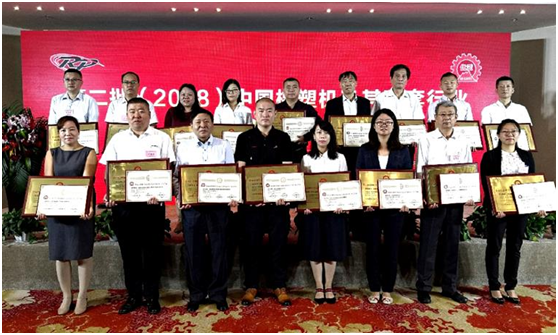

Arp Technology Won 2018 “Quality Products” Award For China Rubber And Plastic Machinery And Its Supporting Industries

National Rubber and Plastic Design Technology Center, National Rubber and Plastic Machinery Information Center, and Rubber and Plastic Technology and Equipment magazine are evaluation agencies for high-quality and innovative products in rubber and plastic machinery industry. The second batch of national rubber and plastic machinery industry high-quality and innovative product professional evaluation award-winning enterprises have been announced. The “bolster-free self-adaptive mold-adjusting hydraulic tire curing press” developed by Arp Science and Technology has won 2018 China Rubber and Plastic Machinery and its supporting industries “Quality Products” award.

This evaluation of high-quality innovative products in China’s rubber and plastic machinery industry aims to enhance influence and competitiveness of China’s rubber and plastic machinery brand. Winning this award is an affirmation of Arp science and technology! In the future, Arp Science and Technology will continue to intensify research and development on production equipment and product innovation, constantly break through technological innovation, and bring high-quality products and satisfactory services to domestic and foreign customers.

This evaluation of high-quality innovative products in China’s rubber and plastic machinery industry aims to enhance influence and competitiveness of China’s rubber and plastic machinery brand. Winning this award is an affirmation of Arp science and technology! In the future, Arp Science and Technology will continue to intensify research and development on production equipment and product innovation, constantly break through technological innovation, and bring high-quality products and satisfactory services to domestic and foreign customers.

High-quality product introduction: hydraulic tire curing press without bolster self-adaptive mold adjustment

Purpose of product:

The hydraulic tire curing press without bolster self-adaptive mold adjustment is mainly used for curing high-grade semi-steel/all-steel radial tires of various specifications. This product has good reliability and stability. It has invention patents in China, Japan, the United States, Russia, Thailand, Indonesia, etc. It is a high-tech product in Jiangsu Province.

Features of products:

- Remove pressurize bolster, hydraulic cylinder drives top beam to apply mold locking force to the model through top and lower tie rods, so that the weight is reduced, and precision requirement of parts is reduced.

- The end of lower tie rod is connected with a mold locking mechanism, which can be self-adaptively adjusted on XYZ three axes.

- A detection device is arranged at the position of tie rod, so that connection gap can be adjusted adaptively.

- The stability of mold opening and closing can be improved by applying a double safety loop of mold opening and closing and a differential mold opening and closing balance loop.

- The application of AS-I bus technology can save more than 40% of wiring cost and make installation, debugging and maintenance simpler.

- The left and right molds can be controlled independently, with ample space for mold change and maintenance.

- PCI integrated installation, easy installation.

- Short cycle time, efficient hydraulic system.

- New heat shield, thickened heat insulation pad, has been proved to save energy by more than 20%.